Rearing and

feeding our pigs

We control the rearing and feeding of our Iberian pigs on our vast estates in Sierra de Aracena (Huelva).

The selection

of our pigs

We carefully select our pigs and we control the “montanera” period to ensure that the animal has eaten enough acorns and grass to reach its ideal weight, later slaughtering it in our slaughterhouse and cutting room, both located in JABUGO. Feeding based on acorns, fresh grass, truffles, aromatic plants and cereals grown on our pastures.

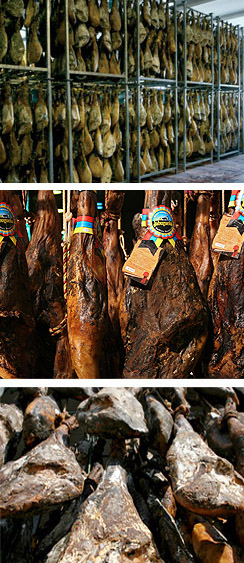

Salting and post-salting

At our installations the hams and shoulders are classified to calculate the ideal salting for each piece. Traditional salting, in stacks, with sea salt and where one day of salt per Kg of weight is established, at a constant temperature and humidity, 3 degrees and 90% respectively.

During post-salting the aim is that the piece achieves safe water activity to prevent possible bacterial contamination, therefore we reduce the relative humidity in order to reach a temperature of 15ºC. This stage lasts for between 90 -100 days.

SALTING WITH NATURAL PRESERVATIVES (Sea Salt). Only when all the factors and processes are controlled do we have the guarantee of having a quality Iberian product. Time and experience act together to give our Iberian Ham the flavor and aroma that make it an exquisite and pleasant snack. That is why our products only have sea salt as a complement.

Elaboration totally handmade with the knowledge acquired generation after generation and with totally natural products, without nitrifying, antioxidants, dyes or sugars.

Enjoy a natural product, with all the guarantees.

Drying

our hams

Once the post-salting stage is over, they go to the natural drying stage where the pieces are exposed to the micro-climate action of JABUGO. This is where "sweating" is produced, because the temperature increases the closer we get to spring.

This is the ham curing process after having salted them to the right point where the taste could turn out to be rather sweeter. They are cured for two years just using the pure Jabugo air. A singular and unique micro-climate that only exists in this sierra that is characterised by summers in which the temperature can change more than 25Cº in one 24 hour period and the Relative Humidity goes from saturation (morning mist called San Juan mist) to relative humidity lower than 30%, creating two fundamental effects that give JABUGO ham unique characteristics that cannot be found anywhere else in the world.

Such high temperature differences cause a dilatation-compression effect on the ham mass which means that the fat, when it is diluted due to the temperature effect, is absorbed by the muscle and then, during the night when the temperature lowers enough, this fat is solidified and is trapped in the muscle tissue, giving it the characteristics JABUGO texture and flavour. The relative humidity, so high during the summer periods and that does not exist in other IBERIAN HAM producing areas, favours the rate of muscle water activity in such a way that it stays unusually high and, therefore, the proteolysis reactions stay active when in the other Iberian ham producing areas they have already stopped. The prolongation of these types of proteolysis reactions means that an extraordinarily high amount of GLUTAMIC ACID is released in comparison with the other producing areas, which generates the extraordinary potential of some nuances (essential oil aromas, etc ), the UMAMI TASTE, which does not appear in hams cured outside this unique micro-climate.

The Cellar, the secret

of its legendary

fungal flora.

In the Cellar the hams finish their last maturing stage in which, in this case, due to the specific micro-climate and micro-flora, after at least two years in semi-darkness, they will have acquired an unmistakable aroma and bouquet. The temperature and humidity in our cellars is stable 24 hours a day, with very little difference between summer and winter. Humidity (75-80%) and temperature 17-18 degrees (summer) and 12-15 degrees in winter. The tastes and aromas are established in the cellar, the bouquet appears and the much appreciated UMAMI taste emerges. The fungal flora also grows (mould) as a result of the chemical processes (proteolysis, lipolysis,…)